00352 - 27 28 15 38 | mycon@mycon.lu

BEST PRACTICE GUIDE ON ASBESTOS

TABLE OF CONTENTS

4 MATERIALS CONTAINING ASBESTOS

4.1 Introduction

4.2 What needs to be done

5 RISK ASSESSMENT AND WORK PLAN BEFORE CARRYING OUT THE WORK

5.1 Introduction

5.2 What to do

5.3 Sample Work Plan Checklist

6.1 Decisions needed

6.2 Guide to decisions on asbestos-containing materials in buildings

6.3 Decisions on the obligation to report work

7.1 Introduction

7.2 Content of the training

7.3 Training programme - your task

7.4 Information

8.1 Equipment required

8.2 Maintenance of equipment

8.3 Your mission

9 GENERAL PRINCIPLES FOR MINIMISING EXPOSURE

9.1 General considerations

9.2 Your mission

10 WORK THAT MAY INVOLVE EXPOSURE TO ASBESTOS

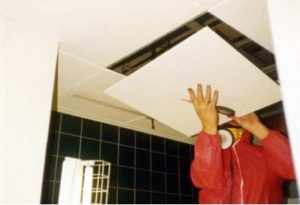

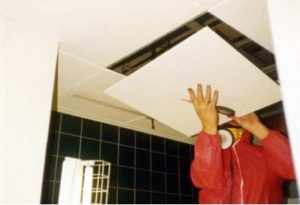

11 LOW-RISK WORK WITH ASBESTOS

11.1 Definition of low risk work

11.2 General procedures for low risk work

11.3 Examples of low risk work

12 NOTIFIABLE WORKS WITH ASBESTOS

12.1 Introduction

12.2 General procedures for notifiable works

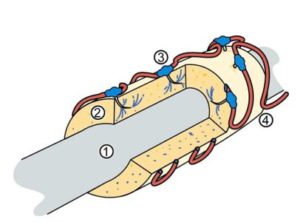

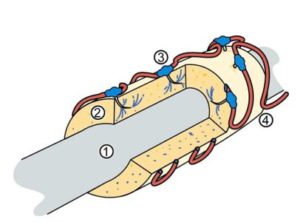

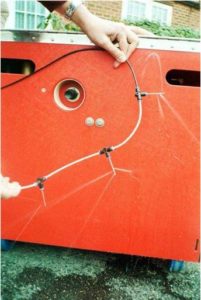

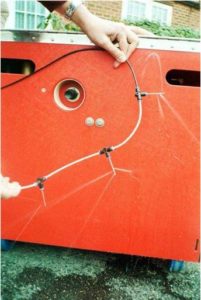

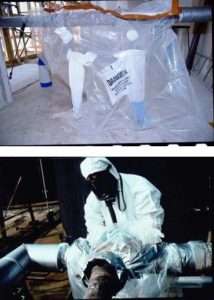

12.3 Enclosure for the execution of asbestos removal works

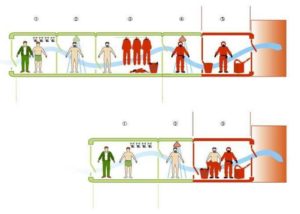

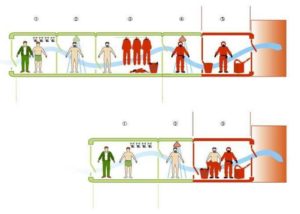

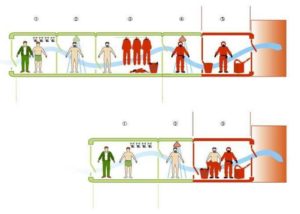

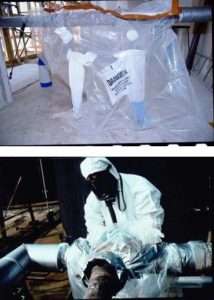

12.4 Decontamination of persons

12.5 Dust suppression techniques

12.6 Encapsulation and housing

12.7 Inspection, monitoring and maintenance of the enclosure

12.8 Waste disposal

12.9 Cleaning and completion of work

14 THE EMPLOYEE AND THE WORKING ENVIRONMENT

14.1 Introduction

14.2 The employee

14.3 The nature of the work

14.4 The working environment

15.1 Introduction

15.2 Problems

15.3 Registration of transport

15.4 Duties of the employee

16.1 Introduction

16.2 Indoor air sampling and sample analysis methods

16.3 Air monitoring objectives

16.4 Selecting a monitoring organisation

16.5 What needs to be done

16.6 Information

17.1 Who else is involved?

17.2 Involvement in asbestos work planning

17.3 Retained asbestos-containing materials

17.4 References

17.5 Was sie tun sollten

18 ASBESTOS IN OTHER PLACES (VEHICLES, MACHINERY, ETC.)

18.1 Introduction

18.2 A variety of applications

18.3 Procedures to avoid exposure to asbestos

18.4 Problems in special cases

FOREWORD

The European Conference on Asbestos Risk, held in Dresden in 2003 and attended by representatives from many European countries, the European Commission and the ILO, drew attention to the fact that asbestos remains the most important toxic carcinogen in the workplace in most countries. With an estimated 20,000 deaths from lung cancer and 10,000 cases of mesothelioma per year in the industrialized countries of Western Europe, North America and Japan, it is clear that asbestos exposure remains a major health problem that must be put back on the agenda and given top priority in our prevention activities. Asbestos remains at the heart of all measures to safeguard workers' health.

In accordance with European legislation, the marketing and use of products or substances containing asbestos was prohibited from January 2005 (Directive 1999/77/EC). Even stricter measures to protect workers against the risk of exposure to asbestos fibres have been in force since 15 April 2006 (Directive 2003/18/EC, which supplements Directive 83/477/EEC). However, despite this legal framework, in practice, the problem of preventing exposure to asbestos during removal, demolition, maintenance or servicing activities remains. Furthermore, in times of close economic ties and globalisation, we must be careful not to thwart our efforts by re-importing asbestos-containing materials.

In line with the recommendations of the Dresden Declaration, the Senior Labour Inspectors Committee (SLIC) set up a working group to develop guides to good practice for activities involving the risk of exposure to asbestos and to conduct a European campaign in 2006 to monitor the implementation of the relevant directives.

The "Best Practice Guide

helps to identify and raise awareness of the presence of asbestos and asbestos products in the use, maintenance and repair of installations, equipment and buildings

describes best practice for asbestos disposal (including dust suppression, dust containment and protective equipment) and for the handling of asbestos cement products and waste.

supports an approach to protective equipment and clothing that takes into account human factors and individual differences

It will be made available to employers and workers.

The labour inspection campaign will be carried out during the second half of 2006 in all EU Member States to protect the health of workers in all work involving the maintenance, demolition, removal or disposal of asbestos-containing materials. Inspections will be carried out by national labour inspectorates (and health authorities if they are competent). The objective of the campaign is to support the implementation of Directive 2003/18/EC (which complements Directive 83/477/EEC), which should be implemented by all EU Member States by 15 April 2006. The inspection campaign is preceded by information and education activities.

For our partners outside Europe, the labour inspectorates of the EU Member States offer their support. Existing SLIC training materials, 2006 campaign materials and good practice guides can be used in any other country wishing to address the health risks associated with asbestos and its use. For this purpose, ILO Convention 162 can be used as a minimum standard. This Convention and the examples of best practice represent the minimum level below which the international community should not fall.

Dear reader,

This "Practical guide to best practice in the prevention or reduction of risks from asbestos in work involving (or likely to involve) asbestos" is the result of a joint collaboration between the Senior Labour Inspectors Committee (SLIC) and the employers' and workers' representatives on the Advisory Committee on Safety and Health of the EU Committee and represents a further step towards the abandonment of asbestos in European workplaces. We hope you will read this guide and keep it to hand.

The main target groups are employers, workers and labour inspectors.

- For the employer, the guide provides information on the latest technical, organisational and personal safety and health measures that the employer is required to implement.

- For the worker, the guide provides information on protective measures, focusing on the key points where

the worker must be trained and motivated to actively contribute to safe and healthy working conditions.

and not harmful to health. - For the labour inspector, the guide describes the main aspects to be examined during the inspection visit.

The guide is complemented by a dedicated website of the European Agency for Safety and Health at Work where you will find additional information and specific links to national health and safety websites concerning the risk of exposure to asbestos.

In addition to its use in the 2006 asbestos inspection campaign, the guide aims to provide a common European basis of good practice for all those involved in work-related asbestos exposure.

exposure to asbestos, the guide aims to provide a common European basis for best practice.

| Dr Bernhard Brückner Deputy Director Department of Health and Safety Place of work Hessian Ministry of Social Affairs Germany | Mr Jose-Ramon Biosca de Sagastuy Head of Institution Head of Institution DG Labour, Social Affairs and Equal Opportunities Health, safety and hygiene at work Luxembourg |

1. INTRODUCTION

This guide has been developed by the Senior Labour Inspectors Committee (SLIC) in collaboration with the Social Partners' Advisory Committee on Safety and Health (ACSH) (representatives of trade unions and employers) with the aim of providing labour inspectors, employers and workers across Europe with a common source of information accessible to all. Developed to support the 2006 asbestos campaign, this guide should continue to be useful in the future. It should therefore evolve with future advances in best practice.

The scope of this guide is ambitious in that information is presented on three scenarios:

- Work in which asbestos may be involved (e.g. in buildings where there is a risk of unexpected discovery of asbestos due to incomplete documentation or incomplete removal).

- Work where low exposure to asbestos dust is expected.

- Work involving an increased risk of exposure to asbestos dust and carried out by specialist companies.

For this reason, the guide includes several chapters relating to all three scenarios, as well as specific chapters on each scenario.

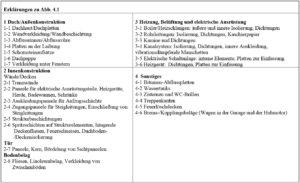

- Chapters 1 to 4 provide basic information. These chapters describe what asbestos is, its health effects, the materials containing asbestos and where they are found.

- Chapters 5 to 7 describe the planning and preparatory work to be carried out before the work is carried out, for example: risk assessment; preparation of written instructions (or the work plan); the process for deciding what work to carry out and whether it should be considered notifiable; whether medical surveillance is required; training of personnel

- Chapters 8 to 12 describe the practical organisation for carrying out work where workers are or may be exposed to asbestos. Chapter 8 describes the equipment required, Chapter 9 describes the general approach to asbestos control, Chapter 10 describes the codes of practice for maintenance work where there is a risk of exposure to asbestos, Chapter 11 describes the codes of practice for low risk work and Chapter 12 describes the codes of practice for notifiable asbestos work (e.g. asbestos disposal).

- Chapters 13 to 18 deal with specific aspects: demolition work (Chapter 13), the worker and the working environment (Chapter 14), waste management (Chapter 15), monitoring and measurement (Chapter 16), other persons with special functions, e.g. the client, architects and facility managers (Chapter 17), and asbestos in other situations, e.g. in vehicles and machinery (Chapter 18).

Chapter 19 describes medical surveillance

Working with asbestos can involve working at great heights, in high temperatures and with cumbersome and restrictive protective equipment. As this guide focuses on the prevention of health risks from asbestos, it should be noted that other risks (e.g. falls from height, possibly due to a friable asbestos cement roof) should not be ignored.

As regards technical rules and practices to control and minimise the risks related to exposure to asbestos, there are marked differences in approach between the Member States. In general, each approach has certain advantages and disadvantages. This guide provides explanations and clarifications on the different methods that could be considered as "best practice" for a particular approach and situation.

To select the methods to be included in the guide, the following criteria were used:

- the method is reliable and proven

- the method takes into account the characteristics of the different action instructions and should therefore theoretically be the best method

- the method is the best method in the given circumstances

- Progress in the state of work

In preparing the guide, care has been taken to make it as concise and readable as possible and to avoid repetition. For this reason, there are some cross-references between different sections, for example, to explain only once the considerations for the selection and use of protective clothing.

In a concise guide covering a wide range of practical work, details may be omitted. These omissions should not be interpreted as a deliberate exclusion of other measures.

Directive 2003/18/EC (Protection of workers from the risks related to exposure to asbestos at work), which supplements Directive 83/477/EEC, has been implemented in the Member States by national legislation, the practical details of which may vary. This guide is intentionally presented as non-mandatory in order to offer best practice advice without specifying whether best practice is a mandatory requirement under the national legislation of EU Member States. Annex 1 provides a list of relevant national legislation submitted by each Member State.

As this guide focuses on the prevention of risks related to asbestos exposure, it does not claim to cover the requirements of Directive 92/57/EEC on health and safety on temporary or mobile construction sites. For example, in addition to sanitary facilities for the decontamination of persons, adequate rest rooms must be provided, as for all work on temporary or mobile sites. Where a health and safety plan is required under the Health and Safety Directive for temporary or mobile work sites, it must include safe and secure working conditions.

procedures for working with asbestos and documentation of asbestos on site (e.g. disposal certificate).

This guide contains advice specifically for the employer, the employee and the labour inspector. However, readers are likely to find the advice for others informative as well. A chapter has also been included specifically for other groups of people involved in asbestos work, for example, clients contracting for asbestos removal, or people occupying a building after asbestos removal, or health and safety advisers.

The guide aims to give practical advice on removing and reducing exposure to asbestos dust. It focuses on good and best practice for reducing exposure to asbestos.

2 ASBESTOS

Asbestos is the fibrous form of several naturally occurring minerals. The main forms are :

- Chrysotile (white asbestos)

- Crocidolite (blue asbestos)

- Amosite (brown asbestos)

- Actinolite

- Anthophylite

- Tremolite

The first three forms were the main forms of asbestos used in commerce. Although they are known by their colour, they cannot be reliably identified by their colour alone. Laboratory analysis is required for this purpose.

Asbestos can be present in a range of products (see Chapter 4). If fibres can be released, there is a danger of inhaling asbestos fibres in the air we breathe. The microscopic fibres can be deposited in the lungs, remain there for many years and cause disease years later, usually decades.

The weak attachment of asbestos fibres in the product or material due to the brittleness or condition of the product/material increases the risk of fibre release. However, if the fibres are firmly bound to a material that is not brittle, fibre release is less likely. Procedural rules have been introduced in several EU Member States that give priority to the disposal of asbestos-containing materials that are considered more hazardous.

All forms of asbestos have been classified as class 1 carcinogens, which means that they cause cancer in humans. EU Directive 2003/18/EC (Protection of workers from the risks related to exposure to asbestos at work), which supplements Directive 83/477/EEC, requires that workers' exposure to all types of asbestos should not exceed 0.1 fibres/ml. Exposure to all types of asbestos must be reduced to a minimum and must in any case be below the limit value.

Some Member States require that the type of asbestos be taken into account when deciding the priority of a hazard. For example, epidemiological evidence indicates that for a given fibre concentration (measured by the standard workplace method) crocidolite is more dangerous than amosite, which in turn is more dangerous than chrysotile. However, this does not change the practical need to apply best practice to avoid exposure to asbestos.

This guide provides practical advice on how to avoid or minimise exposure to asbestos.

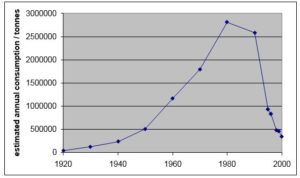

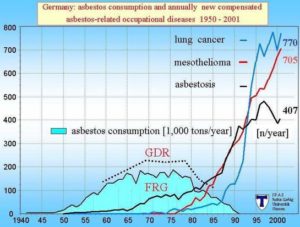

The annual consumption of asbestos in Europe has changed considerably during the 20th century, as shown in Figure 2.1. The data (for consumption in more than 27 European countries according to Virta (2003)) clearly show that consumption increased sharply from about 1950 to 1980, and then decreased when some Member States introduced restrictions on the use of asbestos or banned it completely. The bans introduced by the EU directives in the 1990s accelerated the phase-out of asbestos. A complete ban on the use and marketing of asbestos-containing products (as a result of EU Directive 1999/77/EC) came into force on 1 January 2005. The ban on asbestos mining and the ban on the manufacture and processing of products containing asbestos (following Directive 2003/18/EC) came into force in April 2006. Therefore, the asbestos problems that persist in Europe can be attributed to asbestos in buildings, installations or equipment.

There are also significant differences between the EU Member States. Some countries reduced the use of asbestos from around 1980, while others continued to use it until the end of the century.

Fig. 2.1 Estimated total asbestos consumption in Europe from 1920 to 2000 (Data source : Virta (2003))

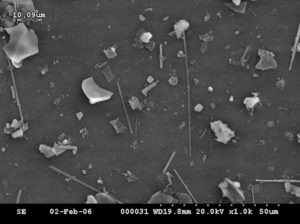

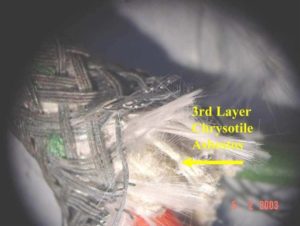

Fig. 2.2 Scanning electron micrograph showing chrysotile fibres

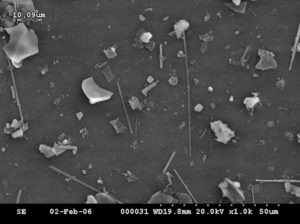

Fig. 2.3 Scanning electron micrograph showing amosite fibres

Asbestos is dangerous because the very fine fibres are not visible to the naked eye. Inhaling these fine asbestos fibres can lead to one of three diseases

- asbestosis, a scarring of the lung tissue

- Lung cancer

- Mesothelioma, a cancer of the pleura (pleura: the thin, slippery skin covering the lungs) or the peritoneum (peritoneum: the slippery skin covering the abdomen).

Asbestosis impairs breathing and can contribute to death. Lung cancer leads to death in about 95 % of cases. Asbestosis can also be followed by lung cancer. Mesothelioma is not curable and usually results in death within 12-18 months of diagnosis.

It has been suggested that exposure to asbestos can lead to laryngeal cancer or gastrointestinal cancer. Oral ingestion of asbestos fibres (e.g. in contaminated drinking water) has been suspected as a cause of gastrointestinal cancer, and at least one study has shown an increased risk due to abnormally high concentrations of asbestos fibres ingested through drinking water. However, these suspicions have not been (systematically) supported by the results of relevant studies.

Exposure to asbestos fibres can also lead to pleural plaques. These are discrete thickened, fibrous or partially calcified areas on the surface of the pleura, which can be detected on an X-ray or CT scan. Deposits on the pleura are not malignant and do not usually lead to limitation of lung function.

In Europe, there are thousands of deaths from asbestos-related diseases every year. At a conference on asbestos in 2003 (organised at the instigation of the EU Senior Labour Inspectors Committee (SLIC)), the likely number of deaths per year in a total of seven European countries (UK, Belgium, Germany, Switzerland, Norway, Poland, Estonia) was estimated to be around 15,000.

http://www.hvbg.de/e/asbest/konfrep/konfrep/repbeitr/takala_en.pdf .

At this conference, the relationship between asbestos consumption in Germany and the delayed onset of newly compensated asbestos-related diseases was described by Woitowitz using the graph shown in Figure 2.1. Delayed onset means that new cases of asbestos-related diseases will continue to occur due to exposure to asbestos during peak periods of asbestos use. Although the production of asbestos-containing products and materials has been phased out in the EU, there is still a risk of exposure to asbestos from materials and products that are still in buildings, installations and equipment.

Fig. 3.1 Annual asbestos consumption and annual incidence of disease in Germany (Source: Woitowitz (2003)

http://www.hvbg.de/e/asbest/konfrep/konfrep/repbeitr/woitowitz_en.pdf

In the UK, there were around 1900 deaths from mesothelioma in 2001, 2002 and 2003, and the incidence of mesothelioma is expected to peak between 2011 and 2015 at between 2000 and 2400 deaths per year.

http://www.hse.gov.uk/statistics/tables/meso01.htm

It is estimated that lung cancer deaths from asbestos exposure are about twice as high as mesothelioma deaths. Thus, the total annual number of deaths from asbestos-related cancer in the UK alone is currently estimated to be around 5,500 to 6,000.

In countries where awareness of the dangers of asbestos is not yet as high, cancer diagnoses and statistics (especially for mesothelioma, which is difficult to diagnose) may be less reliable.

These diseases generally develop over longer periods of time and usually do not occur earlier than 10-60 years after the first exposure to asbestos. The average latency period from first exposure is about 35 to 40 years for mesothelioma. The average latency period for lung cancer has been estimated to be about 20-40 years. There is no direct experience of adverse effects from the inhalation of asbestos fibres.

Asbestosis usually develops following years of heavy exposure to asbestos, and the disease usually occurs more than a decade after the initial exposure. The cases of asbestosis that continue to be reported in Western Europe were almost certainly caused by heavy exposure several decades ago.

The risk of developing asbestos-related lung cancer and mesothelioma increases with exposure. The risk of disease is lower if exposure to asbestos is kept as low as possible. However, there is no known threshold below which there is absolutely no risk of developing these cancers. It is therefore important to use best practice to eliminate or minimise the risk of exposure.

It is thought that the risk of developing mesothelioma is greater for people exposed to asbestos fibres at a young age than for those exposed later in life.

It is generally accepted that lung cancer is much more common in smokers than in non-smokers. The risk of developing lung cancer from asbestos exposure is also higher in smokers than in non-smokers.

If you employ people who may be exposed to asbestos in the course of their work, you must. :

- follow best practice (as defined in this guide);

- ensure that people have received appropriate training and have been informed of the risks

- ensure that communication is effective (e.g. not hampered by communication difficulties);

- ensure that people understand the importance of minimising exposure;

- provide information on the increased risks due to the combination of smoking and asbestos exposure in order to encourage smokers to stop smoking;

- comply with legislation relating to work where exposure to asbestos is possible.

If you are likely to be exposed to asbestos in your work, you should. :

- Be aware of the risks associated with asbestos exposure;

- understand that it is important to minimise exposure;

- consider quitting smoking ;

- Follow best practice for working with asbestos, as outlined in this guide.

If you are a labour inspector, you must :

- Determine whether information (posters, brochures, etc.) on the health risks of asbestos exposure is available;

- check whether workers have been properly informed about the increased risk for smokers exposed to asbestos, for example by looking for leaflets or posters and interviewing the persons concerned;

- check that the relevant legislation has been complied with.

4.1 INTRODUCTION

Asbestos was widely used in many applications, e.g. for reinforcement or as thermal, electrical or acoustic insulation material. It has been used in friction products, gaskets and adhesives. Its chemical resistance has led to its use in certain processes, e.g. filtration or electrolytic processes. It has been used in commercial and industrial buildings as well as in private homes, as shown in Figure 4.1. It is also found in insulation materials for railway carriages, ships and other vehicles, including aircraft and some military vehicles.

The extent to which a material releases asbestos fibres depends on whether the material is intact or damaged. The condition of asbestos-containing materials can change over time, for example due to damage, wear and tear or ageing.

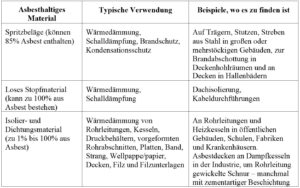

There are significant differences in the fragility of different materials and the ease with which fibres can be released. Table 4.1 summarises examples of asbestos-containing materials and their typical uses. Asbestos-containing materials are listed according to their potential to release asbestos fibres. Materials that are likely to release asbestos fibres easily are at the top of the list. Some asbestos-containing materials (bituminous mixes and rubber or plastic flooring) are flammable. These flammable materials should not be disposed of by burning as this would release asbestos fibres.

Table 4.1 Examples of asbestos-containing materials with indication of asbestos content

The extent to which different types of asbestos-containing materials were used varies considerably between Member States. In some, asbestos was mainly used as asbestos cement. In other Member States (e.g. the United Kingdom), the use of structural cladding (a cladding only a few millimetres thick, containing about 5 % of asbestos) has been popular only at times.

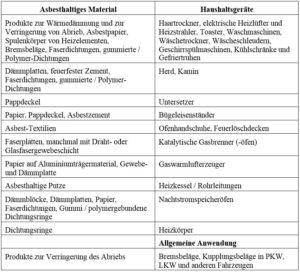

Table 4.2 summarises examples of the use of some of these asbestos-containing materials in household appliances and industrial applications.

Table 4.2 Examples of asbestos-containing materials and products used in household appliances and other applications

Products containing asbestos were manufactured by different manufacturers and offered under different trade names. In many cases, products that contained asbestos in the past were subsequently manufactured without asbestos. An exhaustive list of details of trade names, manufacturers and periods when the manufactured product contained asbestos is available for products sold in France on the INRS website (INRS ED1475,

http://www.inrs.fr/inrs-pub/inrs01.nsf/B20B5BF9E88608EDC1256CD900519F98/$File/ed14 75.pdf ).

Fig. 4.1 The asbestos building shows the typical places where asbestos-containing materials can be found.

4.2 WHAT NEEDS TO BE DONE

There is a possibility of exposure to asbestos when carrying out general maintenance or repair work in buildings. If you are involved in such work in these areas, the advice provided here will be relevant to you:

If you employ or supervise people who may be exposed to asbestos-containing materials in the course of their work (see materials described above), you should :

- provide adequate training so that they recognise materials likely to contain asbestos and know what to do and when to do it if they come into contact with materials likely to contain asbestos;

- obtain reliable and good quality information on the presence or absence of asbestos-containing materials, for example from building plans and/or architects (in some Member States, the responsible person must draw up a list of asbestos-containing materials in a building);

- ensure that records are kept (e.g. by your organisation or the building owner) of materials that are proven to be asbestos-free;

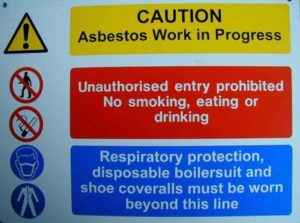

- provide written information on the presence of known asbestos-containing materials on the site, including an asbestos inventory and, where appropriate, appropriate warning signs;

- provide written instructions on the procedures to be followed if asbestos-containing materials are unexpectedly encountered (in accordance with the information provided in chapters 9 and 10).

If your work is likely to release asbestos dust from a material listed above, you must. :

- have received information before the start of the work as to whether or not these building materials contain asbestos;

- know how to recognise products likely to contain asbestos;

- know what to do if you come across asbestos-containing materials (see Chapters 5 to 10).

If you are a labour inspector, you must :

- check that workers carrying out maintenance work have been adequately trained to recognise materials that may contain asbestos;

- check that adequate information is available on the materials that do or do not contain asbestos;

- check that organisational arrangements are in place to ensure laboratory analysis of samples of materials likely to contain asbestos;

- check whether there is a responsible person who can order the immediate interruption of work if materials likely to contain asbestos are discovered;

- check that the relevant national legislation is complied with.

Fig. 4.2 Enclosure with asbestos insulation board (partially removed to show the asbestos cement flue behind).

Fig. 4.3 Asbestos insulation board as a partition wall. This example shows the practical problems of constructing a suitable joint and the areas where asbestos dust can accumulate during removal.

Fig. 4.4 Hole in wall reveals asbestos pipe insulation

Fig. 4.5 An asbestos cement flue sealed with an asbestos bead passes through an asbestos filler.

Fig. 4.6 Asbestos-containing floor tiles

Fig. 4.7 Asbestos-containing roofing felt

Fig. 4.8 Asbestos insulation of steam pipes

Fig. 4.9 Cables insulated with a layer of asbestos in the insulation

Fig. 4.10 Asbestos cement lining in a factory

Fig. 4.11 Asbestos insulation on steel beams

Fig. 4.12 Closing a chimney door with an asbestos cord. On the right, a close-up of the asbestos cord.

5 RISK ASSESSMENT AND WORK PLAN BEFORE CARRYING OUT THE WORK

5.1 INTRODUCTION

When preparing a risk assessment and work plan, it is good practice to document the assessment and the information used for it in writing.

In order to obtain information on the location of asbestos, an investigation by competent professionals may be necessary. The procedures for carrying out such surveys are not covered in this guide, but it is important that the responsible person (employer, manager, worker) is aware that they are required. The information should be provided in a form that is easy to understand.

Where information is provided, it is important to respect the limitations indicated in the information. For example, not all wall cavities may have been tested during an inspection.

In some Member States, there may be a policy of removing asbestos (especially weakly bound asbestos) where possible. In this case, the discovery of the presence of asbestos may trigger the need to comply with legislation requiring safe removal.

In other Member States, the decision on what to do with the asbestos-containing material is based on a review of factors relating to the risk of asbestos fibres being released from the material. This decision-making process is described in Section 6.2. Subject to this decision, asbestos-containing material may remain where it is and be treated as a non-hazardous hazard, provided that the material is well maintained, well sealed, documented (e.g. on building plans) and appropriately labelled.

Asbestos that is not removed must be regularly inspected to ensure that the material remains in good condition. In addition, it must be stated that the organisation and control of the proximity work is effective. If the asbestos is not in good condition or cannot be maintained in a safe condition, removal must be arranged.

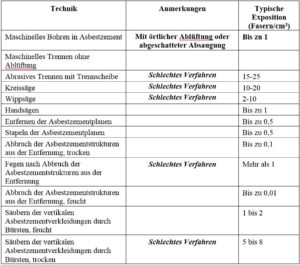

If it has been decided to carry out work in areas where asbestos-containing materials are encountered or asbestos dust is released, a written assessment of the hazard and associated risks should be prepared. The risk assessment should be site specific, i.e. include the specifics of the site, and should include an assessment of potential exposures and a summary of available experience in controlling exposure to asbestos in similar circumstances. The risk assessment should take into account the risks of exposure to asbestos for workers as well as for other relevant persons in the vicinity (e.g. residents). This may be based on measurements from similar or previous work. Typical exposure concentrations measured by the UK Health and Safety Executive for work involving asbestos coatings, plasters and insulation boards are given in Appendix 1.

Written instructions (sometimes called a 'written work plan') should be prepared for each task.

The conditions under which work with asbestos is carried out create some practical difficulties with regard to emergencies, such as sudden incapacitating illness or injury. Access may be limited (especially if the work is carried out in an enclosure, see Chapter 12) and the wearing of breathing apparatus impedes communication. Emergency procedures should cover accidents and illnesses within an enclosure. This requires the following information:

- Number and names of rescuers

- Identification of first responders (if all persons are wearing protective clothing and full face respiratory equipment).

- the organisation of communication between people inside and outside the enclosure (especially in case of emergency)

- quick emergency access points to a compound, and when and how to use them

- Access procedures for emergency personnel

- the location of exits and emergency equipment

- Detailed decontamination procedures to be followed after an emergency access (e.g. access to assist an injured and immobilised worker in the enclosure).

The emergency procedures should also specify the measures to be taken in the event of an emergency evacuation of the building or site (for example, after a fire or bomb threat) by workers wearing personal protective equipment which may be contaminated by asbestos.

Risk assessments and written instructions (work plan) should be freely available on the construction site. They should take account of foreseeable emergency situations and indicate the procedures to be followed and the persons responsible in such an event.

5.2 WHAT YOU MUST DO

If you employ or supervise people who may release asbestos dust in the course of their work, you must :

- have prepared a written risk assessment and a written work plan for each task;

- ensure that the risk assessment takes into account the characteristics of the particular workplace and activities and includes a sufficient basis for estimating potential exposure;

- ensure that the risk assessment takes into account the exposure of all persons involved (e.g. machine operators, local residents, contractors' employees, etc.)

- ensure that the plan is detailed and relevant to the specific site and the work being carried out there;

Include preparatory work in the plan (e.g., erecting an enclosure); - Include in the plan a clear diagram of the site showing the location of equipment (e.g. containment, airlock, decontamination unit, negative pressure units, waste passage, secure contaminant container);

- consult workers with practical knowledge to ensure that the risk assessment and work plan are realistic;

- ensure that copies of the risk assessment and work plan are available on site and available to those involved in the work;

- Ensure that the risk assessment and work plan are explained to staff and those involved in the work;

- ensure that copies of the risk assessment and work plan have been sent to the supervisory authorities if required by national legislation;

- Include procedures for dealing with emergencies (including those described in section 5.1).

If you are about to carry out work that may release asbestos dust, you should

- Be consulted on the risk assessment and work plan;

- offer your suggestions on practical issues affecting the work plan and risk assessment;

- have a copy of the risk assessment and the work plan ;

- Make sure you have the work surface available.

If you are a labour inspector, you should check whether :

- an adequate and appropriate risk assessment is available on the construction site with regard to the exposure of workers and other persons;

- written instructions (work plan) with site-specific details are available on the website;

there is a contingency plan (e.g. as part of the work plan); - workers have an adequate understanding of the risk assessment and the work plan;

- the risk assessment and work plan show that workers' comments have been taken into account.

5.3 SAMPLE CHECKLIST FOR A WORK PLAN

The national regulatory body can provide guidance on the design of work plans (e.g. the "Method Statement Checklist" published by the UK HSE's asbestos licensing unit http://www.hse.gov.uk/aboutus/meetings/alg/policy/02-03.pdf ). A work plan may contain cross-references to general information on working methods, which should be included. The work plan should always be complete and describe all the specific characteristics of the site and the task (e.g. the site layout and any deviations from generally accepted methods).

The following checklist for a work plan is based on the advice of INRS, 1998 ED 815, Annex 6 and the UK Health and Safety Executive's Method statement.

This example is a non-exhaustive list of elements that the work plan should include or take into account. It should also include items relating to notifiable work (see Chapter 12). For low risk work (see Chapter 11), the work plan may be less comprehensive but should include the sections or items marked with an asterisk (*).

*Title page

Under the logo of the organisation carrying out the work:

- Date of issue

- General project title (asbestos removal, encapsulation)

- type of asbestos-containing material

- national licences or permits to carry out the work (if required by national legislation), date and duration of the work

- the name of the person responsible for the work and the name of the client

- the exact address of the site address

- name of the doctor (in EU Member States where a doctor is involved in occupational health and safety)

expected date of arrival of the executing company at the construction site

Administrative information

- Auftragnehmer oder Organisation, die die Arbeiten an den asbesthaltigen Materialien durchführt (Name des Direktors, Vertreter auf der Baustelle; mit Adressen, Telefon- und Faxnummern)

- Personen, die für die Arbeiten verantwortlich sind (Telefon- und Faxnummern)

- Name des ernannten, auf der Baustelle anwesenden Beraters

- the responsible laboratory for the delivery of messages on the premises (address, telephone and fax number)

- Unterauftragnehmer, insbesondere für Vorbereitungsarbeiten

- List of official organisations

* Information on the construction site

- * Location (e.g. shop in a shopping centre)

- * Type of work

- Planned treatment, removal and/or encapsulation

- Type of asbestos (crocidolite, chrysotile)

- Type and condition of asbestos-containing materials, quantity and distribution on the construction site.

- * Work programme, including date and time of work

- Staff

- Daily routine programme

- Designated areas

- Markings (type of signs, number, locations)

- The contaminant removal pathway

- Location of the decontamination unit

- Sanitary facilities and recreation rooms

- Site-specific factors (proximity to other activities, working in high temperatures, air conditioning or heating systems, working at height).

Factors affecting the removal or encapsulation plan

- Analysis of risks related to asbestos and other factors related either to the workplace (e.g. electricity, gas, steam, fire, machinery, working at height) or to the materials and equipment used.

- Measurement of fibre (or asbestos fibre) concentrations prior to intervention

- Likely exposure to asbestos during removal or encapsulation

Setting up the work (enclosure, etc.) on the construction site

- Staff facilities (drinks, sanitary facilities).

- Separation and marking of the area

- Impact on other activities in the building or surrounding area

Preparatory work

- Removal of equipment and materials

- Setting up a supply and disposal network (electricity, water, ventilation)

- Setting up the building systems in the work area (fire alarm, electricity, gas, central heating, air conditioning, etc.)

- Materials and equipment needed for the work

Preparation of the area where the asbestos work will take place

- Separation and closure (see Chapter 12)

- Generation of negative pressure

- Pre-cleaning of the work area and installation objects, removal or covering of installation objects.

- Closing off the area (safe working practices, materials and emergency exits)

- Negative pressure and air extraction

- Smoke tests, processes and acceptance criteria

Asbestos removal or encapsulation

- Methods (injection, spraying, manual scraping, etc.), equipment (injection equipment, spray equipment) and materials (wetting agents, cleaning agents).

- Worker protection (respirator)

- Quality control procedures (working methods and treatment efficiency)

Monitoring programmes (surveillance and measures)

- Sampling plan for the work period (see chapter 16).

- Systems for monitoring and controlling the effectiveness of containment.

- Plan of the locations where sampling is envisaged

Waste removal

- Status of waste (asbestos and non-asbestos containing materials), handling procedures.

- Waste disposal, safe storage on site and procedures for disposal in approved landfills.

Cleaning the work area

- Procedure for removal of surface materials and cleaning of surfaces

- Methods of decontamination of materials and equipment used in the work.

- Visual control and cleanliness check. System to maintain negative pressure. The designated person is responsible for the control systems.

Description and characteristics of materials and equipment used in the work

- Sampling for asbestos dust in indoor air, sampling plan, laboratory handling of the work

- Finally, the removal of the equipment from the

Description and characteristics of materials and equipment used in the work

- Staff equipment (including type of respirator).

- Decontamination unit (and documentation of test methods confirming that it is not contaminated from previous operations)

- Enclosure and associated equipment

- Enclosure size

- Negative pressure units (number and capacity, air change rate)

- Air lock, bag lock

- Water heater, water filter

- Lighting

- Injection equipment and other dust collection equipment

- Emergency equipment

- Consumables (filters, etc.).

Emergency measures

- First aid, emergency measures for situations with different degrees of urgency and danger.

- Procedures used for assistance in emergency pens

- Communication (to call for help from inside the enclosure)

- Coordination with external emergency services

Plans and drawings of the construction site

- Location of the construction site/enclosure in relation to other activities and businesses.

- The enclosure, its size and shape and the location of :

- Display panels and control television (if required)

- Negative pressure units and associated air change points

- Industrial class hoovers (for asbestos)

- Bag lock, waste passage, safe storage of waste (e.g. skip)

- Location of the decontamination unit, passageways (if there is no direct connection between the decontamination unit and the enclosure) and access to the enclosure airlock.

- Location of networks and equipment involved in the work (e.g. air intake points, water and electricity supply to the decontamination unit).

- Positioning of connection points if a network of compressed air supply connection points is used to supply the respiratory protective equipment.

6 ENTSCHEIDUNGSPROZESS

6.1 NOTWENDIGE ENTSCHEIDUNGEN

Dieses Kapitel beschreibt den logischen Entscheidungsfindungsprozess, wenn es darum geht:

- festzustellen, ob es besser ist, die asbesthaltigen Materialien an Ort und Stelle zu lassen (sie dabei ausreichend zu sichern sowie angemessen zu kontrollieren und managen) oder das Asbest zu entfernen

- zu entscheiden, ob bestimmte Instandhaltungsarbeiten so ausgeführt werden können, dass nur eine geringe Gefährdung durch Asbestexposition besteht und sie als Arbeiten mit "gelegentlicher Exposition von geringer Höhe" eingestuft werden können, die ohne vorherige Meldung an die zuständige Behörde ausgeführt werden können.

6.2 ANLEITUNG ZU ENTSCHEIDUNGEN ÜBER ASBESTHALTIGE MATERIALIEN IN GEBÄUDEN

There are a number of key decisions that need to be made before carrying out work in which asbestos-containing materials may be involved. These decisions are closely linked to the risk assessment and planning process (Chapter 5). The hazard assessments will determine the appropriate decisions; these decisions will affect the purpose and content of the plans to be prepared.

There are a number of factors to consider when deciding what work to carry out. In some EU Member States, there is national legislation which in principle requires the removal of asbestos-containing materials (especially materials containing weakly bound fibres) where this is practicable. Other Member States decide whether asbestos-containing materials can be left in place depending on certain criteria, such as condition, location, access and thus the overall likelihood that the material presents a risk of releasing fine asbestos fibres. National legislation must therefore be taken into account when deciding whether materials should be secured (e.g. by encapsulation and/or containment) and can be left in place.

Subject to national legislation, asbestos-containing materials that are in a safe condition (i.e. undamaged, sealed or encapsulated) may be left in place provided that effective control and management of the safe materials is provided. If asbestos-containing materials are left in place, they should be identified in the building records and plans so that their presence can be taken into account in future works. In addition, a system should be in place to monitor asbestos-containing materials and manage their condition (e.g. maintain materials in good repair).

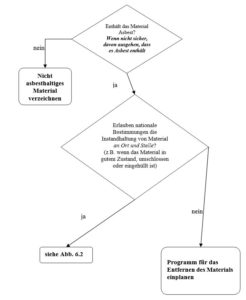

Figures 6.1 and 6.2 show logical decision trees. The starting point is to identify whether a material is asbestos or not. Then a system is used to decide whether the material should be removed or not. Once it is known that the material contains asbestos, a series of questions follows to find out whether the material contains asbestos.

- is in good condition; or

- is difficult to repair

- accessible (in which case it may be damaged accidentally or intentionally; if it is not accessible, its removal may be impeded and limited)

- damaged, with more than minor and superficial damage (such that repair would be unreliable)

- extensive damage (i.e. damage so extensive that encapsulation of the damaged parts is no longer possible)

cannot be encapsulated or enclosed (for reasons other than those mentioned)

If the asbestos-containing material is not in good condition, if it cannot be easily repaired, if it is easily accessible (and therefore potentially subject to further damage or disturbance), if it is badly damaged and if there is no practical way of encapsulating or containing the material, then the material must be removed. This decision applies to any type of asbestos-containing material.

The alternative to removing asbestos-containing materials is to make the materials safe (by keeping them in good condition or enclosing them) and to monitor and manage them in situ.

Although asbestos-containing materials can be made safe and monitored and managed in situ, it is necessary to take into account the potential requirements of normal renovation work in the building. If the materials interfere with normal renovation work in the building, removal of the asbestos-containing materials would be the right decision.

For asbestos cement and other materials with closely related fibres, the decision-making process would probably lead to a decision to leave the material in place, document it, monitor it and manage it.

Fig. 6.1 Decision tree for suspected asbestos materials

6.3 DECISIONS ON THE OBLIGATION TO REPORT WORK

The risk assessment is the basis for deciding whether the work should be treated as notifiable asbestos work.

Directive 2003/18/EC (Protection of workers from the risks related to exposure to asbestos at work), which supplements Directive 83/477/EEC, applies to all workers who may be exposed to dust from materials containing asbestos.

EU Directive 2003/18/EC requires that work be reported (to the supervisory authority of the EU Member State concerned) and that health surveillance of workers be carried out and documented. It also requires employers to keep a register of workers "indicating the nature and duration of their activities and the hazards to which they have been exposed". In certain clearly defined cases, these provisions need not apply. "Provided that the exposure is occasional and low level and that the results of the risk assessment clearly show that the exposure limit value for asbestos in the air in the work area is not exceeded, [the above provisions] need not be applied to the following operations

- short, non-consecutive maintenance operations, working only on non-friable materials.

- Removal of intact materials in which the asbestos fibres are firmly bound in a matrix, leaving the materials intact.

- Encapsulation and packaging of asbestos-containing materials in good condition

- Air monitoring and control and sampling for asbestos in a particular location".

Figure 6.3 shows a procedure for determining whether a job meets the criteria for non-application of the legislation.

The Directive (2003/18/EC) sets the exposure limit for asbestos at 0.1 fibres/cm3, (8-hour weighted average). Some EU Member States determine the hourly average over shorter periods (4 hours or 1 hour).

The national regulations of the Member States may differ as to whether and to what extent use is made of the possibility to derogate from these provisions.

Therefore, all work with friable materials (e.g. sprayed coatings, coatings, loose tamping materials) should be treated as notifiable work and also require medical surveillance. In the case of other materials, the condition must be assessed and a risk assessment carried out in order to obtain the information necessary to make a decision on a possible exemption from the reporting obligation.

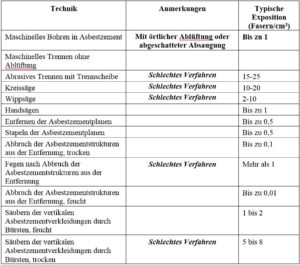

For work involving the handling of fixed fibre materials, e.g. asbestos cement, the risk assessment should take account of the nature and duration of the work. Annex 1 gives examples of air concentrations that have been reported as typical for various activities involving asbestos cement.

If you employ or supervise people who may be exposed to asbestos dust in the course of their work, you must

- Carry out a risk assessment for the work in question;

- Use the decision-making process to determine the appropriate course of action (i.e. whether the material can be removed or secured and left in place and managed, and whether the work should be reported);

- Establish and maintain a written record of the type of material (e.g. sprayed-on cladding or insulation board or asbestos cement) and its condition (e.g. comment on the nature and position of the damage, using photographs if possible);

- Prepare a record of the documents used in the risk assessment to estimate the possible concentration in air;

record the decision process (e.g. answers to questions in corresponding logical decision trees); - Plan the work and organise indoor air measurements, unless there is clear evidence of air concentrations likely to be encountered.

If asbestos-containing materials are likely to be damaged during your work, you must. :

- be involved in the risk assessment that contributes to the above decision-making process.

If you are a supervisor inspecting a construction site where asbestos-containing materials are present, you must :

- examine the evidence that the decision not to remove the material was justified;

- check that the condition of the materials which led to the work being considered non-notifiable in the risk assessment actually meets the criteria described in 6.3 (e.g. non-friable, non-degraded, in good condition);

- ensure that the monitoring and management of materials left behind is carried out;

- check that the information used to estimate likely exposures is adequate, particularly if the risk assessment indicates a low level of exposure.

Fig. 6.3 Decision tree for deciding whether the work is notifiable or not

Fig. 6.4 Asbestos containing insulation board. Removal of the board should be considered as the board can easily be damaged at this stage.

7 INSTRUCTION AND INFORMATION

7.1 INTRODUCTION

This chapter outlines the topics to be covered in a training programme and refers to other publications for further details. In particular, the report by Bard et al (2001), which provides detailed recommendations on the structure and content of an asbestos training programme, provides detailed information for training providers. The European Directive (2003/18/EC) states that "Employers shall provide appropriate training to all workers who are or may be exposed to dust containing asbestos. This training must be provided at regular intervals and must be free of charge for workers. 2. The content of the training must be easily understood by the workers. The instruction must enable workers to acquire the knowledge and skills necessary for prevention and safety...".

The recommendations of a SLIC working group are described at: http://www.ilo.org/public/english/protection/safework/labinsp/asbestos_conf/inforen.pdf. The UK training recommendations are described at: http://www.hse.gov.uk/aboutus/meetings/alg/licence/04-04.pdf.

The training should be presented in a way that is easily understood by the participants (employer, supervisor or worker) and include practical exercises on the use of all equipment. It should be delivered in the language that the workers (especially workers of other nationalities) know and understand.

This chapter also includes brief indications on the required training programme (initial training, refresher courses, regular review of training needs, etc.).

This chapter aims to make it clear to the employer what training he should organise for workers, supervisors and himself. The worker should know what training he is entitled to. This information also serves to provide the labour inspector with a clearly described framework for checking the adequacy and effectiveness of the training.

7.2 TRAINING CONTENT

7.2.1 Essential training content for all asbestos-related work

Training for all persons (employer, supervisor, worker) involved in work where they may (possibly) be exposed to asbestos-containing materials should include the following topics

- the properties of asbestos and its effects on health, including the synergistic effect of smoking

- the different types of materials and products likely to contain asbestos and where they are likely to be found

- the importance of the condition of the material or products for the possibility of asbestos fibre release

- the necessary measures to be taken when materials likely to contain asbestos are encountered

7.2.2 Core training content for general construction

Workers, employers and supervisors who may be exposed to asbestos in the workplace shall receive appropriate training. This training should cover the following elements, in addition to the content listed in section 7.2.1:

- the type and extent of information that should be available where asbestos-containing materials are located (e.g. some EU Member States require inventories on the presence and location of asbestos-containing materials in buildings)

- the obligation to stop work immediately if materials suspected of containing asbestos are encountered and to inform the responsible supervisor

- the measures required to reduce potential exposure if the suspected asbestos material is in poor condition or accidentally damaged (e.g. evacuation of the immediate area, necessary safety measures and informing the responsible supervisor)

- for the supervisor and the employer as recipients: analytical testing of samples in the laboratory to confirm the presence or absence of asbestos.

Training should also cover emergency situations where asbestos is suspected to be present in a material after it has been damaged. In such cases, training should include procedures to ensure that the situation is not exacerbated by inappropriate actions (e.g. attempting to sweep up the material) or by inaction that perpetuates asbestos exposure.

7.2.3 Essential training content for low risk asbestos work

If the training is intended for workers carrying out low-risk work, i.e. work meeting the criteria set out in point 6.3, it must cover the content specified in point 7.2.1 and above:

- Activities that may lead to exposure to asbestos.

- The importance of effective control measures to prevent or minimise exposure to asbestos dust and to prevent the spread of asbestos contamination

- safe work practices that minimise exposure, including control techniques, personal protective equipment, risk assessments and written instructions (work plan)

- The importance of respiratory protective equipment, selection of the appropriate respirator and its correct use

- Proper care and maintenance of personal protective equipment and respiratory protective equipment

- Decontamination procedures for people

- Procedures for the following emergency situations, e.g. accidental damage to asbestos-containing materials or injury or illness to persons while carrying out work on asbestos

- Disposal of the waste, appropriate encapsulation (e.g. bagging or wrapping) of the waste to prevent the spread of contamination, labelling and maintenance of a secure skip or container at the point of transport by a licensed asbestos waste disposal contractor to an approved (or licensed) landfill.

For workers and supervisors, training should include practical exercises to familiarise them with sample materials and to practise the correct use and maintenance of equipment and proper work techniques.

Training for supervisors and employers should also cover legal responsibilities and work supervision.

7.2.4 Essential training content for asbestos removal work

If the training is for workers doing notifiable work (i.e. the hazard being assessed does not meet the criteria for low-risk, limited-scope work set out in Section 6.3), then more comprehensive training is required. This should cover the topics listed in section 7.2.3, but also the nature of the work and the topics relating to the notifiable work.

The training of asbestos removal workers should include practical exercises to learn how to use and maintain safety-related equipment (enclosures, personal protective equipment, respiratory protective equipment, decontamination units, dust removal equipment and equipment for the controlled removal of asbestos-containing materials).

The topics listed in sections 7.2.1 and 7.2.3 are expanded to include the following:

- When discussing the health effects of asbestos, the relationship between exposure and risk of disease should be emphasised in order to highlight the importance of preventing or minimising exposure to asbestos.

- When discussing products that may contain asbestos, detail the characteristics of the products that should be considered when removing them.

- The discussion on safe working practices should also address the following points:

- Good work planning, including good site design (positioning of equipment, e.g. airlocks, decontamination unit, shortest and safest route for transporting waste to a safe skip).

- An appropriate and sufficient risk assessment covering all aspects of the work, and a detailed work plan.

- Site preparation prior to erecting an enclosure/barrier, including any pre-cleaning that may be required.

- Procedures for erecting a partition, extra protection of the floor and any weak points. Ensure that all parts of the wall can be cleaned properly, i.e. there should be no place where dust/dirt can settle. Exhaust airlocks, ventilation airlocks, vision panels (and control TV if required), negative pressure units, including easy to change pre-filters, power supply cables from outside the enclosure so that fuses can be changed, etc.

- Maintenance of an enclosure (ventilation efficiency - negative pressure unit, enclosure integrity, periodic inspections, etc.), including the importance of smoke testing before work begins.

- Techniques for removing asbestos with minimum dust generation, including dust suppression methods such as 'wet stripping', rapid bagging of materials to prevent the spread of dust (onto feet, equipment or clothing) and, for supervisory personnel, monitoring the effectiveness of the operation.

- Cleaning of the enclosure, airlocks and sanitary facilities; complete cleaning (from top to bottom).

- Effective communication (including between people inside and outside the venue).

- Re-cleaning if an enclosure is not released

- Enclosure cleaning and dismantling procedures

- When discussing respiratory protective equipment, the following points should also be addressed:

- Positive pressure ventilation and/or compressed air hood

- Cleaning/maintenance of respiratory protective equipment

- The importance of checking the fit of equipment and the factors that influence it; examination, testing, cleaning and maintenance of respiratory protective equipment.

- The different types of respiratory protective equipment, their advantages and limitations

- Emergency measures to be taken in the event of a power failure (electricity or compressed air) in a work situation

- Possible limitations (e.g. visibility) and difficulties in using respiratory protective equipment.

- Training in emergency procedures would cover procedures to be followed in the following situations:

- Emergency measures for people who are injured or become ill in an asbestos-contaminated area.

- Emergency evacuation (e.g. in case of fire)

- Power or equipment failure (negative pressure, breathing apparatus)

- Leakage outside the enclosure

- Interruption of the water supply to the sanitary unit

- Training in personal decontamination procedures would include the following:

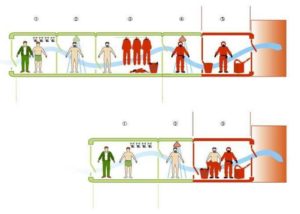

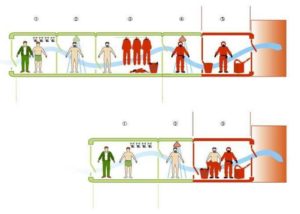

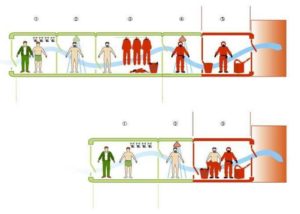

- the use of airlocks, entrance/exit to the enclosure and decontamination unit, which may be either directly connected to the enclosure or separate from it

- Change of personal protective equipment, showers, disposal of suits.

- Maintenance of a decontamination unit

- Decontamination of people in the event of an accident or evacuation

- Correct use and maintenance of equipment used for asbestos removal

- Other potential hazards, for example asbestos removal at high temperatures, working at great heights, setting up and using access equipment at higher workplaces

- Waste disposal :

- Procedures for bagging and packaging waste

- Safe containment (e.g. packaging and/or bagging)

- Marking

- Safe passage through the bag closure and defined path from containment to safe storage site.

- Transport of the waste from the remediation site to an approved landfill by an approved asbestos waste disposal contractor.

- Evidence of waste traceability from the construction site to the landfill (e.g. roadmap).

For workers who are required by the Directive to undergo medical examinations, the training must include the following elements

- The requirements of the health check, including its purpose and importance (as described in Chapter 19) and the need for documentation that it has taken place.

- Information and advice that can be given to workers following a medical examination.

For supervisors and employers, training should also include the following elements

- Good planning

- Inspection and testing of equipment (e.g. decontamination unit, enclosure, dust suppression equipment);

- How to detect defects.

- Inspection of the work during its execution

- Check the effectiveness of fibre concentration control

- Audit of skills and training needs

- Keeping records

- Need for intensive training of new workers

In addition to practical supervision, training for supervisors and employers should address the topics covered in Chapters 5 and 6, namely

- Preparation of a risk assessment (with regard to exposure of workers and others) and a work plan

- relevant laws and regulations

- their functions and responsibilities

Fig. 7.1 Practical exercise in using a Type H hoover to remove a simulated contaminated material (talc). This illustration was provided by the UK HSE.

7.3 TRAINING PROGRAMME - YOUR TASK

If you employ or supervise people who may be exposed to asbestos in the course of their work, you must. :

- provide appropriate initial training, as described above, before they undertake the work;

- assess whether refresher training is required - this should be provided at least annually and when procedures or the nature of the work changes - and keep appropriate records;

- Organise regular task briefings (called 'toolbox talks'), especially if a particular task involves something unusual;

- Organise training by a competent provider (e.g. an organisation or individual with knowledge of appropriate procedures and good working practices and with the skills to deliver the training content);

- ensure that each trainee receives instructions in a language they understand;

- keep a record of the training successfully completed, which must be accessible to anyone in the workplace;

- Ensure adequate supervision in the workplace, with particular attention to newly qualified workers.

If your work involves a risk of exposure to asbestos, you must. :

- Receive appropriate training before undertaking the work;

- Have the need for retraining assessed regularly (at least once a year) and whenever there is a significant change in the nature of the work;

- inform your employer if there are any language problems that may affect your understanding of the training (for example, does your employer know what your first language is?)

If you are a labour inspector, you must :

- check that there is documentation of the training courses successfully completed by each worker on the site;

- check whether there is documentation of periodic assessments of the need for refresher training for each worker;

- check that foreign workers have received training in one or more languages they understand;

- check whether the training was provided by a competent training company/trainer.

7.4 INFORMATION

For all activities where workers are or may be exposed to dust from asbestos-containing materials, Directive 2003/18/EC (Protection of workers from the risks related to exposure to asbestos at work), which supplements Directive 83/477/EEC, requires that workers and their representatives be provided with adequate information on :

- health risks due to exposure to asbestos dust or materials containing asbestos

- legally binding limit values and the need to monitor asbestos dust emissions

- hygiene requirements, including the need to refrain from smoking

- precautions to be taken with regard to the wearing and use of protective equipment and clothing

- special precautions to minimise exposure to asbestos.

These points are included in the training programme recommended above. In addition, information on these issues should also be readily available in the workplace in an appropriate form (e.g. posters, notices or brochures).

8 EQUIPMENT

8.1 EQUIPMENT

Adequate equipment must be available for the job. The basic equipment for most tasks is listed in this section. Equipment should be kept in good condition and therefore maintained as described in Section 8.2.

8.1.1 FOR LOW-RISK WORK (NON-REPORTABLE)

For low risk asbestos work (which does not have to be declared), the equipment required includes the following:

- Equipment to isolate and separate the work area (tapes, barriers, markings, warning signs).

- Materials to prevent the spread of contamination (durable polyethylene sheets of 125 and 250 µm thickness [also known as 500 and 1000 thickness polyethylene sheets], wood, plastic or metal materials).

- Smoke test tubes to check the integrity of the small boxes.

- Personal protective equipment (e.g. disposable overalls, washable boots) and respiratory protective equipment (e.g. disposable asbestos respirators EN 149 type FFP3 or half-masks EN405 - with face fit test to determine suitability for each worker and regular replacement of contaminated filters).

- Type H hoover, i.e. a hoover equipped with HEPA (High Efficiency Particulate Air) filters manufactured according to international specifications for use with asbestos.

- Dust suppression equipment, e.g. local exhaust with connection to a Type H hoover to collect dust from boreholes, etc.

- Appropriate containers for asbestos waste (e.g. properly labelled plastic bags).

cleaning equipment and consumables (wet wipes, dust cloths, airless fine water spray)

safe storage of waste - hygiene facilities for personal decontamination (washing facilities, preferably a shower), with storage facilities for work and protective clothing separate from normal street clothes (see 8.1.2 for personal decontamination facilities required for reportable asbestos work)

- consumables for personal decontamination (shower gel, nail brushes, towels)

- Water filtration equipment

8.1.2 Additional equipment for reportable work

For notifiable work with asbestos, you must also have the following:

- a complete enclosure (durable polyethylene sheet, frame and negative pressure unit with pressure monitoring equipment; one EU Member State requires pressure monitoring equipment that continuously records readings).

- the enclosure should have its own observation windows or television surveillance to allow inspection of the structure and workers without having to enter the enclosure

- Good lighting (movable, cleanable lamps suitable for use in the enclosure).

- smoke generators to check the integrity of large enclosures

- high performance full-face respirators (with personnel who have completed face-fit tests for this type of respiratory equipment); or air-supplied respirators

- personal protective equipment (disposable suits and washable boots)

- A fully cleanable decontamination unit with an adjustable heated shower and separate areas for clean and discarded contaminated work clothes. There must be a certificate confirming that the decontamination unit has been tested and found to be uncontaminated prior to its arrival on site. There should be at least one shower (decontamination unit) for every four workers engaged in asbestos work.

- the filtration of waste water prevents the spread of asbestos.

- best practice (used in some EU Member States) is to use a five-chamber unit with two shower rooms (see section 12.4 for a diagram showing the layout and appropriate use of decontamination equipment). This five-chamber system is used when workers wear impervious coveralls that are cleaned in a shower. After removing the washable suit, which can be stored in the middle chamber, the worker uses the next shower chamber. A widely used and accepted alternative is a three-tiered unit consisting of a shower between a "clean end" and a "dirty end"; this system is suitable for workers wearing disposable suits.

- A High Efficiency Particulate Air (HEPA) exhaust filter provides airflow (through grilles) from the "clean end" to the "dirty end" of the decontamination unit. Self-closing doors separate the sections. During cold seasons, the clean end must be heated to provide a warm and comfortable environment for changing and showering.

- A negative pressure unit (exhaust fan with HEPA filter) to maintain ventilation inside the enclosures, with a control unit to monitor the pressure. Best practice (as defined in one EU Member State) is to use continuously recording monitoring devices (e.g. by recording the pressure difference on paper). One Member State requires the negative pressure unit to comply with a national quality standard (British Standards Institution; PAS 60 Part 2).

- For notifiable work (Chapter 12), in particular for the removal of materials containing only weakly bound asbestos, one EU Member State requires an emergency generator to supply ventilation

key electrical equipment (negative pressure ventilation, lighting, etc. in the enclosure) and water storage tanks sufficient to provide water for the recommended personal decontamination. (The equipment should only be used by competent and appropriately trained personnel).

- Dust suppression equipment for injecting water into asbestos-containing insulation prior to removal and for spraying the surfaces of asbestos-containing materials.

- Safe storage of asbestos waste

This list is not exhaustive, but it shows the amount of equipment needed to be protected against the risk of exposure to asbestos. Other equipment (such as fire extinguishers and first aid equipment) is also needed.

8.1.3 Selection of respiratory protective equipment

The EU Directive 2003/18/EC states that for activities (such as repair, maintenance, removal and demolition) which may generate asbestos concentrations above the permissible exposure limit value (for the value, see section 6.3), the employer must specify additional measures to protect workers, in particular that "workers shall be provided with appropriate respiratory protective equipment and other personal protective equipment to be worn". Therefore, appropriate respiratory protective equipment should be selected based on the risk assessment (Chapter 5). Guidance on the selection, use and maintenance of respiratory protective equipment is available in EN 529.

Selection should be based on the following principles:

- the concentration inside the mask should be kept as low as possible, but never exceed the exposure limit.

- the equipment must be suitable for the worker and the conditions in which he or she works

- the nature of the work, B. the range of motion required, and any barriers or restrictions

- The conditions on the site, e.g. the possibility of access and free movement in the work area

- The individual conditions of the head of the face

- Its medical fitness

- The conditions under which the wearer must use the equipment

- Wearing comfort, in relation to the conditions of the particular site, so that workers wear the equipment correctly for the required period of time

One EU Member State recommends that :

- The use of disposable respiratory protective equipment (EN FFP3) should be limited to situations where the concentration does NOT exceed 10 times the exposure limit and where exposure lasts for a relatively short period. The flexibility of the mask provides comfort, but it also causes mask deformation - particularly in demanding work - which in turn can lead to leakage when the mask and face are tightly fitted.

- A half mask with a P3 filter offers slightly more protection than a disposable respirator, as the half mask offers a more reliable seal to the face.

- Battery operated respirators (caps, coveralls) with a P3 filter are more suitable for longer or more difficult work.

- Full face masks (or suits) supplied with compressed air (also known as SCBA) should be used where concentrations may exceed 50 times the exposure limit.

Another EU Member State (the UK) provides tables of protection factors that can be used to select the most appropriate protective equipment for the situation, see Tables 8.1 and 8.2 below. The protection factors in the table also show that EN FFP3 disposable respirators are not suitable if the airborne concentration exceeds 20 times the exposure limit. A self-contained breathing apparatus (or an independent breathing apparatus) should be used when concentrations exceed 40 times the exposure limit.

The performance of masks (such as filter masks, full face masks and half masks) is highly dependent on maintaining a good seal between the user's skin and the mask. As the shape of the face varies greatly from person to person, one size or type of respirator may not be suitable for all faces. Therefore, it is important that :

- A face fit test is part of the procedure for selecting appropriate respiratory protective equipment.

- wearers of respiratory protective equipment should be involved in the selection process, as this ensures that the equipment chosen is suitable for them and that they will accept and use it correctly

Facial fit testing and wearer participation may be mandatory according to national legislation or guidelines.

Beards, sideburns or even visible beards affect the sealing effect of the face mask. Workers with these characteristics will need respiratory protective equipment that does not rely on a face seal (e.g. caps or actively ventilated suits).

Wearing conventional goggles also prevents a satisfactory seal. However, there are full-face masks that allow special frames to be attached to the inside of the mask.

EU Directive 2003/18/EC also states that where respiratory protective equipment is required to be worn, "it shall not be permanent but shall be limited to an absolute minimum time for each worker. During the period of activities requiring the wearing of personal respiratory protective equipment, rest breaks shall be provided in accordance with national laws and practices, depending on the physical and climatic exposure and, where appropriate, in consultation with the workers and/or their representatives.

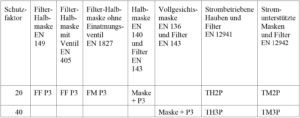

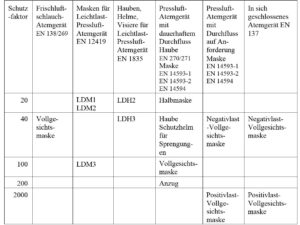

Table 8.1 Types of respiratory protective equipment available for protection against asbestos dust

Table 8.2 Types of respirators available for protection against asbestos dust

8.1.4 Correct use of respiratory protective equipment